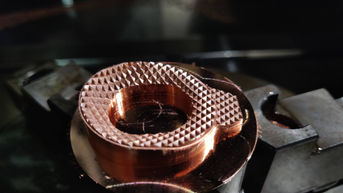

DMC-845L Mill Center Travel: X Axis Travel: 800 mm | Y Axis Travel: 400 mm | Z Axis Travel: 500 mm Axes Type (X/Y/Z): Linear Roller / Linear Roller / Linear Roller Spindle Nose to Table: 110 - 535 mm Tool to Column: 435 mm Motors (X/Y/Z): 0.85 / 0.85 / 1.35 kW Direct Drive Spindle Taper: BT40 / CAT40 Spindle Diameter: 127 mm Spindle RPM: 50-8000 RPM Spindle Motor: 5.5 kW (7 HP) Belt Drive Spindle Rated Torque: 36 N-m Tool Changer: 8-Station Independent Arm Max Tool Specs: Ø63 mm / 5 kg Max Rapid Speed (X/Y/Z): 20 m/min Positioning Accuracy: 12 um Repeat Accuracy: 6 um Table Size: 850 x 420 mm Table Slots x Offset x Width: 4 x 85 mm x 18 mm Max Table Load: 200 kgs Machine Weight: 3800 kg Shipping L x W x H: 2200 x 2000 x 2310 mm Machine L x W x H: 2200 x 2200 x 2310 mm Coolant Capacity: 200 L Air Requirements: 6 kg/cm2 Power Requirements: 15 kVA, 3 Phase, 220V Machine Features: Standard Features: Automatic 4-Way Tool Changer CNC Rigid Tapping C3 Class Precision Ball Screws Auto Lubrication System Full Enclosure Flood Coolant System & Chip Recovery Tray LED Work Light Tri-color Light Post Tools and Toolbox One Year Warranty on All Parts Options: 10,000 RPM Spindle with Chiller Through Spindle Coolant 4th Axis Rotary Table Chip Auger System Tool Setter for Length Measurement Tool Length, Diameter Measurement System Spindle Probe System

VMC-855L Travel: X Axis Travel: 800 mm | Y Axis Travel: 550 mm | Z Axis Travel: 550 mm Axes Type (X/Y/Z): Linear Rails + Roller / Linear Rails + Roller / Linear Rails + Roller Spindle Nose to Table: 120 - 670 mm Tool to Column: 590 mm Motors (X/Y/Z): 1.8 / 1.8 / 2.9 kW Direct Drive Max Torque X/Y/Z Thrust: 28.7 / 28.7 / 54 Nm 10707 N (2407 lbf) Spindle: Diameter: 150 mm Taper: BT40 / CAT40 Base Spindle: 8000 RPM Belt-Drive, 7.5 kW (10 HP) Rated S1, Air Cooled Optional Spindle: 12000 RPM Direct-Drive, 11 kW (15 HP) Rated S1, Spindle Chiller Oil Cooled, Coolant Thru Spindle Option ATC: Tool Changer: 24-Tool Arm Type Max Tool Specs: Ø80 mm (Ø3.15”) Diameter, 200 mm (11.81”) Length, 8 kg (17 lbs) Weight Motion: Max Rapid Speed X/Y/Z: 36 m/min (1417 IPM) Max Cutting Feed X/Y/Z: 24 m/min (945 IPM) Positioning Accuracy: 0.006 mm (0.00024”) Repeat Accuracy: 0.003 mm (0.00012”) Table: Table Size: 1000 x 550 mm Slots x Offset x Width: 5 x 90 mm x 18 mm Max Table Load: 500 kg (1100 lbs) Install: Floor Space W x L x H: 2830 x 2875 x 2860 mm (112” x 114” x 113”) Shipping / Machine Weight: 5800 kg (12760 lbs) Control Specifications: 15.6" Touchscreen LCD Display 16 GB Program Storage 2 USB, 1 LAN 4-Axis Synchronous ISO G-Code Motion Interpreter Core Conversational Programming DXF CAD Drawing + Import via Touch File Send / Receive thru LAN / USB FTP Networked File Server Remote Diagnosis & Support Remote Monitoring and Reporting Dynamic 10,000 Block Look Ahead Program Retrace, MPG Run Machine Features: 24-Tool Arm Type Tool Changer Rigid + Peck Tapping C3 Class Precision Ball Screws Auto Lubrication System Full Enclosure Flood Coolant System & Chip Recovery Tray LED Work Lights Tri-color Light Post Tools and Toolbox One Year Warranty on All Parts Additional Options: 12,000 RPM Direct Drive Spindle with Through Spindle Coolant (TSC) 4th Axis Rotary Table Tool Setter System Spindle Probe System Chip Conveyor System CE / UKCA Safety and Electrical

VMC-1100L: Travel: X Axis Travel: 1100 mm | Y Axis Travel: 600 mm | Z Axis Travel: 600 mm Axes Type (X/Y/Z): Linear Rails + Roller / Linear Rails + Roller / Linear Rails + Roller Spindle Nose to Table: 120 - 720 mm (4.72-28.35") Tool to Column: 650 mm (25.59") Motors (X/Y/Z): 2.9 / 2.9 / 4.4 kW Direct Drive Max Torque X/Y/Z Thrust: 54 / 54 / 71.6 Nm 26860 N (6038 lbf) Spindle: Diameter: 150 mm Taper: BT40 / CAT40 Base Spindle: 8000 RPM Belt-Drive, 11 kW (15 HP) Rated S1, Air Cooled Optional Spindle: 12000 RPM Direct-Drive, 15 kW (20 HP) Rated S1, Spindle Chiller Oil Cooled, Coolant Thru Spindle Option ATC: Tool Changer: 24-Tool Arm Type Max Tool Specs: Ø80 mm (Ø3.15”) Diameter, 200 mm (11.81”) Length, 8 kg (17 lbs) Weight Motion: Max Rapid Speed X/Y/Z: 36 m/min (1417 IPM) Max Cutting Feed X/Y/Z: 24 m/min (945 IPM) Positioning Accuracy: 0.006 mm (0.00024”) Repeat Accuracy: 0.003 mm (0.00012”) Table: Table Size: 1200 x 600 mm (47.24‘’x 23.62‘’) Slots x Offset x Width: 5 x 100 mm x 18 mm (5 x 3.94” x 0.7) Max Table Load: 800 kg (1760 lbs) Install: Floor Space W x L x H: 3300 x 3020 x 2970 mm (130” x 119” x 117”) Shipping / Machine Weight: 7000 kg (15400 lbs) Control Specifications: 15.6" Touchscreen LCD Display 16 GB Program Storage 2 USB, 1 LAN 4-Axis Synchronous ISO G-Code Motion Interpreter Core Conversational Programming DXF CAD Drawing + Import via Touch File Send / Receive thru LAN / USB FTP Networked File Server Remote Diagnosis & Support Remote Monitoring and Reporting Dynamic 10,000 Block Look Ahead Program Retrace, MPG Run Machine Features: 24-Tool Arm Type Tool Changer Rigid + Peck Tapping C3 Class Precision Ball Screws Auto Lubrication System Full Enclosure Flood Coolant System & Chip Recovery Tray LED Work Lights Tri-color Light Post Tools and Toolbox One Year Warranty on All Parts Additional Options: 12,000 RPM Direct Drive Spindle with Through Spindle Coolant (TSC) 4th Axis Rotary Table Tool Setter System Spindle Probe System Chip Conveyor System CE / UKCA Safety and Electrical

HSM-650 | HSM-650S Travel: X-Axis Travel: 600 mm | Y-Axis Travel: 500 mm Z-Axis Travel: HSM-650: 300 mm HSM-650S: 270 mm Nose to Table: 150 ~ 450 mm Ground to Table: 700 mm Spindle: Spindle Taper: HSK40E Spindle RPM: 24000 RPM Spindle Power: 7.5 kW Spindle Torque: 6.1 Nm Cooling System: Oil-Air ATC: ATC Type: Carousel Magazine Size: 12 Tools Max Tool Dia x Length: 50 mm x 200 mm Max Tool Weight: 3 kg Table: Table Size (W x H): 700 x 500 mm Table Slots: 5 x 100 x 14 mm Max Table Load: HSM-650: 300 kg HSM-650S: 350 kg Motion: Axis: XYZ, Power, Type 2.0 / 1.3 / 2.0 Kw XYZ Rotary: 1.3 / 1.3 / 2.0 Kw Rapid Speed: 15 m/min Cutting Feed: 10 m/min Positioning Accuracy: 0.007 mm Repeat Accuracy: 0.004 mm Installation: Machine Weight: HSM-650: 4200 kg HSM-650S: 3800 kg Floor Space (L x W x H): HSM-650: 2640 x 3000 x 2460 mm HSM-650S: 2400 x 2800 x 2200 mm Coolant Capacity: 50 L Air Requirements: 6 kg/cm2 Power Requirements: 3 Phase, 208 to 230 V, 50 A Control Specifications: 12.1“/15“ Touchscreen LCD Display 16 GB Program Storage 2 USB, 1 LAN 4-Axis Synchronous ISO G-Code Motion Interpreter Core Shop Floor Conversational Programming DXF Drawing Import via Touch File Send / Receive thru LAN / USB FTP Networked File Transfer Remote Diagnosis & Support Remote Monitoring and Reporting Up to 10K Block Look Ahead Program Retrace, MPG Run MPG Handwheel Electrical Cabinet Heat Exchanger Machine Features: 24,000 RPM HSK40E Embedded Spindle 12 Tool Carousel Type ATC Spindle Chiller Unit Coolant Pump Work Light Tri-Color Light Post Auto-Lubrication System Coolant and Chip Recovery System One Year Warranty on all Parts Additional Options: General Options: Contact Type Tool Length Measurement Non-contact Type Tool Measurement and Breakage detection System Spindle Probe System Spindle Chiller with PID +/- 0.2°C Control HSM-650S Options: CE Spec (for CE Regions) 30,000 RPM HSK40E Spindle 24 Tool Carousel Type ATC X, Y, Z Linear Scale Encoders Dual A+C Rotary Table with Glass Scale

All Videos

All Videos

DynaPath Lathe Conversational Programming Demo

DynaPath DMC-845 / Mach MDS-845 Intro and Dry Run Demo

DynaPath Mill Conversational DXF 2.1 Programming Demo v2